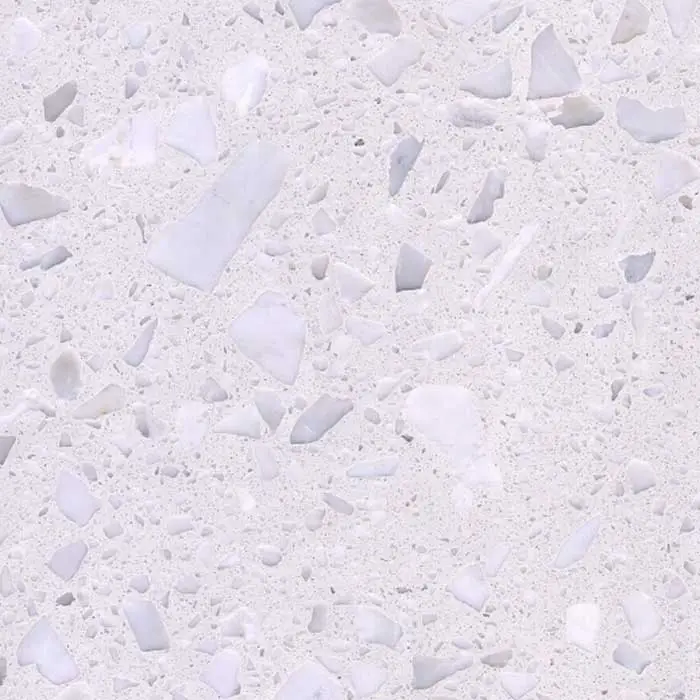

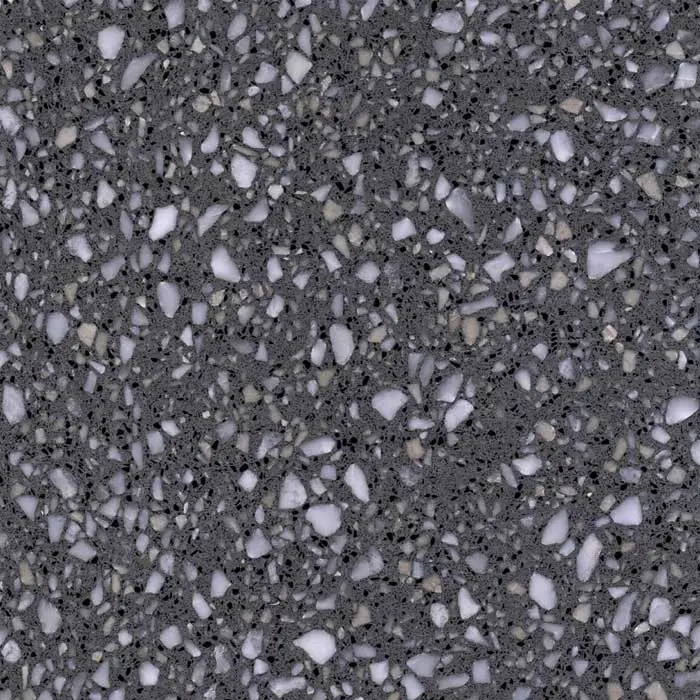

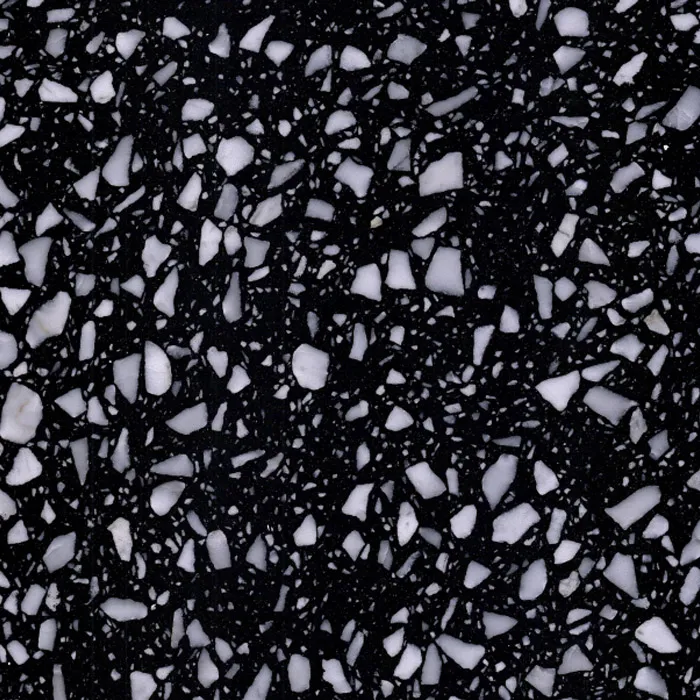

With the popularity of green environmental protection and retro trends, terrazzo stone tile has once again become a popular choice for architectural decoration. This beautiful, durable and versatile floor is not only widely used in commercial and public places, but has also gradually entered the home decoration market.

So, how is terrazzo stone flooring made? How long does the entire manufacturing process take? This article will answer these questions in detail and introduce the production process and time schedule of terrazzo stone flooring.

What is Terrazzo Stone Flooring?

Terrazzo stone flooring, also known as ground stone flooring, is a composite floor material made by mixing cement, sand, gravel, pigment and other materials and undergoing a series of processes. Its characteristics include high hardness, wear resistance, beauty and easy maintenance, and it is widely used in various places such as shopping malls, supermarkets, hotels, schools, hospitals, etc.

How to Make Terrazzo Ceramic Tile?

The manufacture of terrazzo ceramic tile includes multiple steps such as raw material preparation, ingredient mixing, pouring and compaction, preliminary curing and maintenance, grinding and polishing, and sealing protection. Each step has an important impact on the final quality and appearance of the floor. The following are the detailed manufacturing process steps:

1. Raw material preparation

The first step in manufacturing terrazzo stone flooring is to prepare the required raw materials, including cement, sand, gravel and pigment. The specific steps are as follows:

● Cement: Select high-quality cement to ensure good adhesion and durability.

● Sand: Use clean, dry sand with uniform particles and no impurities.

● Gravel: Select gravel of different colors and sizes and match them according to design requirements.

● Pigment: Select pigments that meet environmental protection standards to mix terrazzo stone flooring of different colors.

2. Batching and mixing

After the raw materials are prepared, they need to be batched and mixed in a certain proportion. The specific steps are as follows:

● Batching: According to the design requirements, weigh the cement, sand, gravel and pigment in proportion.

● Mixing: Pour the prepared raw materials into the mixer, add appropriate amount of water, and mix them thoroughly until a uniform slurry is formed.

3. Pouring and compacting

The mixed slurry needs to be poured and compacted immediately to ensure the density and flatness of the floor. The specific steps are as follows:

●Pouring: Pour the mixed slurry into the pre-prepared mold or on the ground, spread it evenly, and ensure uniform thickness.

●Compacting: Use a vibrator or compactor to compact the slurry, expel air, and ensure the density and strength of the floor.

4. Preliminary curing and maintenance

The slurry after pouring and compaction needs to be initially cured and maintained to enhance the strength and durability of the floor. The specific steps are as follows:

●Preliminary curing: After the slurry is poured, let it stand for 24-48 hours for preliminary curing, and keep it moist during the period to avoid cracks and deformation.

●Curation: After the initial curing, carry out a 7-14 day maintenance, sprinkle water regularly to keep it moist, and ensure that the cement is completely cured.

5. Grinding and polishing

After the floor is cured, it needs to be polished and polished several times to obtain a smooth and flat surface and good gloss. The specific steps are as follows:

●Rough grinding: Use a coarse grinding wheel for preliminary grinding to remove uneven parts of the surface and reveal the color and pattern of the stone.

● Fine grinding: Use a fine grinding wheel for further grinding to trim the surface and make it smoother.

● Polishing: Use a polishing machine and polishing powder for final polishing to make the floor surface as bright as a mirror and present a high gloss.

6. Sealing and protection

The floor after grinding and polishing needs to be sealed and protected to enhance its stain resistance and durability. The specific steps are as follows:

● Sealing: Apply a layer of sealant on the surface of the floor to fill the tiny pores and prevent stains from penetrating.

● Protection: According to needs, a layer of protective wax or protective film can be applied on the sealant to further enhance the wear resistance and protective performance of the floor.

How Long Does it Take to Make Terrazzo Stone Flooring?

The production time of terrazzo stone flooring depends on the time arrangement of each process step and the specific construction conditions. The production process generally takes 15-25 days. The following is a rough estimate of the time for each process step:

1. Raw material preparation and ingredient mixing

●Time: 1-2 days

●Note: Raw material preparation and ingredient mixing can usually be completed within 1-2 days, depending on the project scale and raw material supply.

2. Pouring and compaction

●Time: 1-2 days

●Note: Pouring and compaction is a continuous process, which usually needs to be completed within 1-2 days to ensure the uniformity and density of the slurry.

3. Initial curing and maintenance

●Time: 7-14 days

●Note: Initial curing takes 24-48 hours, and the maintenance period is 7-14 days. During this period, the floor needs to be kept wet to ensure that the cement is completely cured.

4. Grinding and polishing

●Time: 3-5 days

●Note: Grinding and polishing usually need to be performed multiple times, and each grinding and polishing takes a certain amount of time, and the overall time is 3-5 days.

5. Sealing and protection

●Time: 1-2 days

●Description: The application and drying time of sealant and protective film is usually 1-2 days.

What Factors Affect the Production Time of Terrazzo?

The production time of terrazzo stone tile will be affected by many factors, including climate conditions, construction environment, process flow and staffing. Here are some of the main influencing factors:

1. Climate conditions

Climate conditions have an important influence on the curing and curing process of terrazzo stone flooring. In an environment with high temperature and humidity, cement cures faster and the curing time can be appropriately shortened; conversely, in an environment with low temperature and humidity, the curing speed is slower and the curing time needs to be extended.

2. Construction environment

The construction environment also has a certain impact on the production time of terrazzo stone flooring. Factors such as the preparation of the construction site, site conditions, and traffic convenience will affect the construction progress. For example, if the construction site has good site conditions and convenient transportation, the transportation of raw materials and construction arrangements will be smoother, and the production time can be shortened.

3. Process flow

The manufacturing process of terrazzo ceramic tile has a direct impact on the production time. Different process flows and technical standards will lead to different production times. For example, the use of efficient mixing and pouring equipment can shorten the batching and pouring time; the use of advanced grinding and polishing technology can improve the grinding and polishing efficiency and shorten the overall production time.

4. Staffing

The number and technical level of construction workers will also affect the production time of terrazzo stone tile. Sufficient construction workers and high-level technical workers can improve construction efficiency and shorten the production time; conversely, insufficient construction workers or low technical level may prolong the production time.

Conclusion

In summary, the manufacturing process of terrazzo stone flooring includes multiple steps such as raw material preparation, batching and mixing, pouring and compaction, preliminary curing and maintenance, grinding and polishing, and sealing protection. The entire production process takes 15-25 days, depending on factors such as climatic conditions, construction environment, process flow and staffing.